China Injection Molding for Beginners

Wiki Article

China Injection Molding Can Be Fun For Anyone

Table of ContentsNot known Details About China Injection Molding Rumored Buzz on China Injection MoldingThe Facts About China Injection Molding RevealedThe Ultimate Guide To China Injection MoldingUnknown Facts About China Injection Molding

By lowering any of these times, the production price will be decreased. The injection time can be decreased by minimizing the maximum wall surface thickness of the component as well as the part quantity. The cooling time is also lowered for lower wall surface thicknesses, as they require much less time to cool right with.Finally, the resetting time depends on the maker size as well as the part size. A larger part will certainly require bigger motions from the equipment to open, close, as well as expel the part, and also a larger equipment calls for more time to carry out these operations. The tooling price has 2 main elements - the mold and mildew base and also the machining of the dental caries.

A majority calls for a bigger, a lot more costly, mold and mildew base. The expense of machining the dental caries is affected by almost every facet of the part's geometry. China injection molding. The main price driver is the size of the dental caries that must be machined, measured by the forecasted location of the cavity (equal to the forecasted location of the component and predicted openings) and its depth.

How China Injection Molding can Save You Time, Stress, and Money.

, with the volume used of the former being significantly higher.: 13 Thermoplastics are widespread due to characteristics that make them highly suitable for injection moulding, such as simplicity of recycling, adaptability for a vast selection of applications,: 89 and also capacity to soften and also flow on home heating.

In multiple cavity moulds, each cavity can be the same as well as form the same components or can be special and form numerous different geometries throughout a solitary cycle.

When sufficient material has actually gathered, the material is compelled at high stress as well as rate into the component forming dental caries. The exact quantity of shrinkage is a feature of the material being used, and also can be relatively predictable. To stop spikes in pressure, the procedure typically makes use of a transfer position representing a 9598% complete cavity where the screw shifts from a consistent velocity to a continuous stress control.

9 Simple Techniques For China Injection Molding

The packing stress is used up until the gateway (cavity entry) solidifies. Due to its little size, the gateway is generally the first place to strengthen with its entire thickness.: 16 Once the gate strengthens, no more material can get in the tooth cavity; appropriately, the screw reciprocates and gets material for the next cycle while the product within the mould cools so that it can be expelled and also be dimensionally steady.The residence time can be lowered by reducing the barrel's volume ability as well as by maximising the cycle times. These factors have actually resulted in the use of a thermally separated, cool shot unit that infuses the reacting chemicals right into a thermally isolated warm mould, which enhances the price of chemical Get More Information responses and cause shorter time called for to achieve a strengthened thermoset component.

After that, the mould closes and the procedure repeats. Pre-moulded or machined elements can be inserted right into the cavity while the mould is open, enabling the material infused in the next cycle to develop and strengthen around them. This process is referred to as Insert moulding as well as allows single parts to contain several materials.

, entrance marks, and also ejector pin marks are typically existing on the final part.: 98 None of these functions are commonly desired, however are inescapable due to the nature of the process (China injection molding).

The 8-Minute Rule for China Injection Molding

The plastic injection moulding industry has actually advanced for many years from creating combs as well as buttons to generating a substantial variety of products for numerous industries consisting of vehicle, medical, aerospace, customer items, toys, plumbing, product packaging, as well as construction.: 12 Examples of polymers best matched for the process [edit] Most polymers, sometimes described as materials, may be used, consisting of all thermoplastics, some thermosets, as well as some elastomers - China injection molding.Offered products include alloys or blends of formerly created materials, so item designers can select the material with the most effective set of buildings from a huge selection. Significant criteria for choice of a material are the stamina and feature needed for the final component, as well as the price, but additionally each material has various parameters for moulding that need to be taken into account.: 6 Various other factors to consider when selecting a shot moulding material consist of flexural modulus of elasticity, or the level to which a material can be curved check without damage, as well as warm deflection and water absorption.

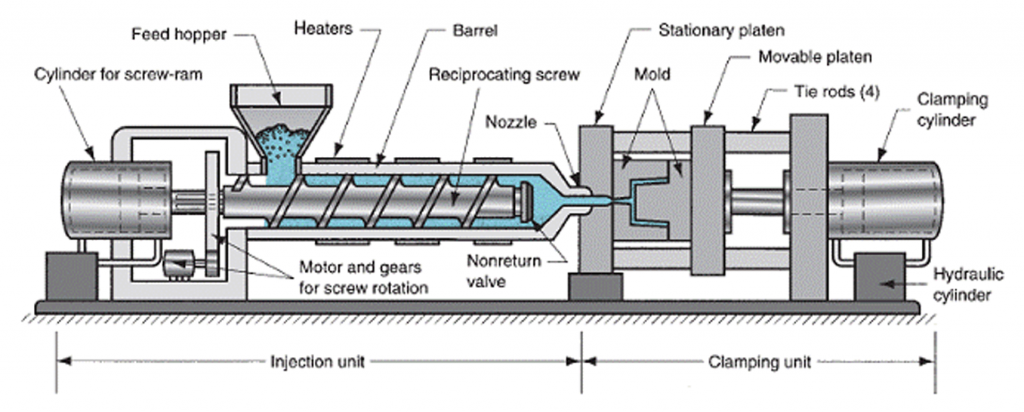

Applications consist of clasps for anchoring as well as disconnecting outdoor-equipment webbing. Shot moulding equipments consist of a product receptacle, an injection ram or screw-type plunger, as well as a home heating unit.: 240 Also known as platens, they hold the moulds in which the elements are formed. Presses are ranked by tonnage, which expresses the amount of clamping force that the maker can apply.

Tonnage can differ from less than 5 loads to over 9,000 lots, with the greater numbers utilized in fairly go to these guys couple of production procedures. The complete clamp pressure required is determined by the projected area of the component being molded. This predicted location is increased by a clamp pressure of from 1.

The Best Strategy To Use For China Injection Molding

2 tons for each and every square centimetre of the predicted areas. As a guideline of thumb, 4 or 5 tons/in2 can be used for the majority of products. If the plastic material is really rigid, it requires even more injection pressure to load the mould, as well as thus extra clamp tonnage to hold the mould closed.: 4344 The needed force can additionally be figured out by the material made use of as well as the size of the component.Report this wiki page